-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

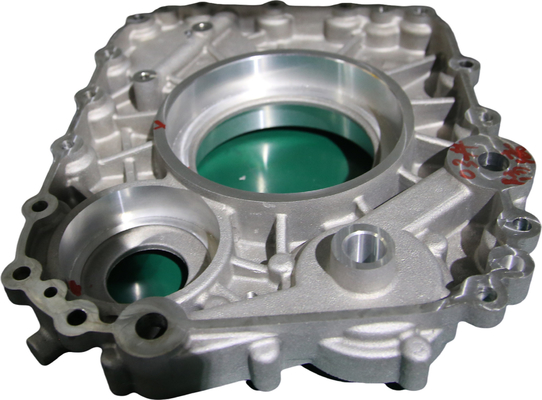

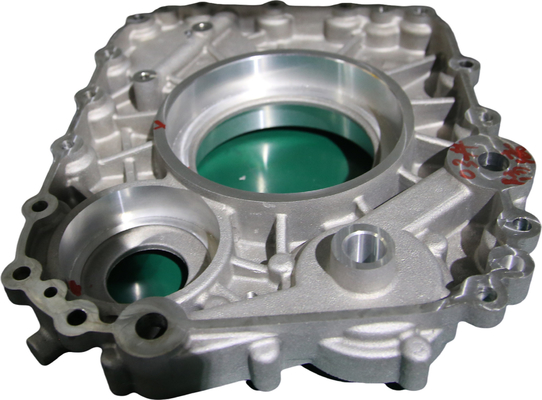

Low Pressure Aluminum Alloy Casting Car parts Engine Casing

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Aluminum Alloy Casting | Mold Material | Aluminium |

|---|---|---|---|

| Application | Car Parts | Mould Life | 50,000-100,000 Shots |

| Surface Treatment | Spray Paint Electroplating | Customized | Yes |

| Average Wall Thickness | >3mm | Usage | Engine Casing |

| Highlight | Low Pressure Aluminum Alloy Casting,Engine Casing Aluminum Alloy Casting,Car parts Aluminum Alloy Casting |

||

Low Pressure Aluminum Alloy Casting Car Aprts Engine Casing

The die casting mold contains the mold cavity, i.e. the space which forms the contours and dimensions of the casting. The liquid die casting alloy is fed in via channels which is called the gating system.

A die casting mold is essentially made of two parts and consists of the fixed (stationary) and the movable (ejector) mold halves. The stationary die half is mounted on the die casting machine’s fixed fixing plate; the ejector die half is fixed to the movable fixing plate and contains the casting ejector. When ready for casting, the two mold halves are closed and are kept closed on the machine by the die locking force. The contact surface between the two mold halves is called the mold parting or mold parting plane. The opening and closing movements are only applied to the ejector die half. Cavities or undercuts are demolded by mechanically or hydraulically operated core slides (cores).

Features of Aluminium Gearbox Housing

1. die casting parts in aluminum such as ADC12, ADC10, A380 & A356.A360

2. Customer's drawing or sample will be highly followed up. The drawing in STP or IGS format will be helpful.

3. Surface: coating, Painting, E-Coating. Phosphate, sand blast, Dying....etc.

4. Flexible cooperation term, small orders for testing is acceptable.

|

Product Name

|

Low Pressure Aluminum Alloy Casting Car Aprts Engine Casing

|

||

|

Size

|

customized

|

||

|

Color

|

As your requirements

|

||

|

Material

|

Aluminum

|

||

|

Application

|

Auto parts, ,Light fixture, lamp cover, led light housing,heat sink or any other type of die casting parts

|

||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Our Advantages

1. We are the biggest lost foam mould manufacturer in China, we focus on high challenge lost foam mould and we have large gantry machining centers,30 sets imported high speed machining center,more than 40 sets general machine tool equipment;

2. We have 36 senior mould designers, to ensure reasonable / safety / high efficiency mould design and ensure the fast mould delivery and rational mould structure, make the process more safer and the production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe, with water spray system, to get a nice cooling effect;

6. We Have (TEF10N) coating on the mould surface, it can reduce the friction, anti water/static electricity/acid-base/high-temperature, with this we can ensure the pattern has smooth surface without distrotion, and easy to demould;

7. All the screws we using stainless steel screw, easy to disassemble during maintenance;

8. For the big mould chest, we using 18-20mm thick wrought aluminium plate, to offer high strenght cavity ;