-

Aluminum Alloy Casting

-

Pressure Die Casting Mould

-

Metal Casting Molds

-

Aluminium Die Casting Mould

-

EPS Foam Mould

-

Lost Foam Mould

-

Sand Casting Mould

-

Permanent Mold Casting Aluminum

-

Aluminium Gravity Die Casting

-

Die Cast Aluminum Tooling

-

Auto Parts Mould

-

Multi Cavity Mold

-

Cylinder Head Mold

-

High Precision Mold

-

Rapid 3d Printing Service

-

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future.

Greg HenkThanks for your kindly hospitality. Your company is very professional , we will have nice cooperation in the near future. -

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

Lionel LoboGood company with nice service and high quality and high reputation. One of our reliable supplier , goods are delivered in time and nice package.

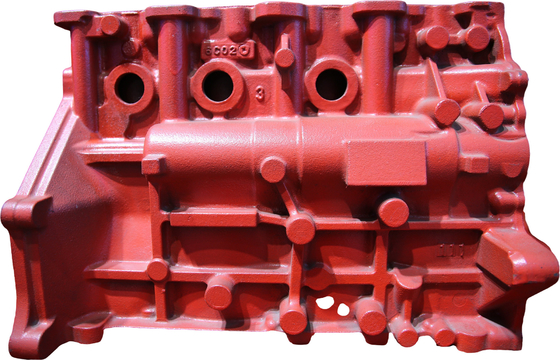

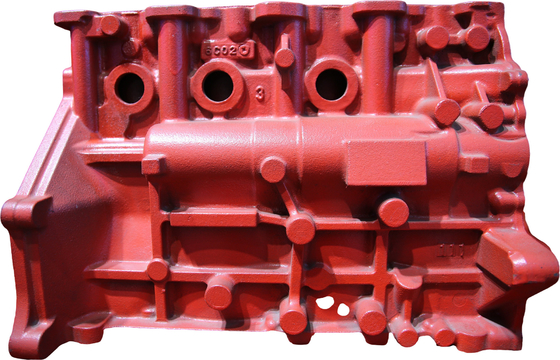

Four Stroke Cylinder Head Mold Four Cylinder Block

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Four Cylinder Block | Demoulding | Automatic |

|---|---|---|---|

| Using Hardness | >HRC45 | Stroke | Four-Stroke |

| Surface Treatment | Heat Treatment | Average Wall Thickness | >3mm |

| Product Range | Light,Industrial,furniture | Type | Lost Foam Casting |

| Highlight | Four Cylinder Block Cylinder Head Mold,Four Stroke Cylinder Head Mold,Head Mold Four Cylinder Block |

||

Four-Stroke Cylinder Head Mold Four Cylinder Block

Uses for Motorcycles:

Motorcycles with four-cylinder engines are common because they offer a nice mix of power, smoothness, and compact design. Because inline-four engines can generate high RPMs and power outputs, they are frequently used in high-performance sportbikes.

Examples are the Yamaha YZF-R6, Kawasaki Ninja ZX-6R, and Honda CBR600RR.

Vehicles:

Four-cylinder engines are often found in sedans, compact automobiles, and some mid-size SUVs since they are economical and produce enough power for daily use. Performance-focused cars also tend to have turbocharged versions.

Ford Focus, Toyota Corolla, and Honda Civic are some examples.

Other Automobiles:

Four-cylinder engines are used in small trucks, vans, and even certain lightweight commercial vehicles because of their combination of power and efficiency.

Engine Cycle:

- Four-Stroke Cycle: Most four-cylinder engines operate on a four-stroke cycle (intake, compression, power, and exhaust). This cycle is efficient and provides a good balance of power and fuel economy, making it ideal for a wide range of vehicles.

- Two-Stroke Cycle: Less common in four-cylinder configurations, but some high-performance or older models may use this cycle, which completes a power cycle in two strokes of the piston.

|

Product Name

|

aluminum mould die casting

|

||

|

Size

|

customized

|

||

|

Color

|

As your requirements

|

||

|

Material

|

Aluminum

|

||

|

Application

|

Auto parts, ,Light fixture, lamp cover, led light housing,heat sink or any other type of die casting parts

|

||

|

Service

|

OEM/ODM

|

||

|

Product's Design

|

Customized as customers' drawings or samples

|

||

Manufacture Process

1. Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5. Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Our Advantages

1. We are the biggest lost foam mould manufacturer in China, we focus on high challenge lost foam mould and we have large gantry machining centers,30 sets imported high speed machining center,more than 40 sets general machine tool equipment;

2. We have 36 senior mould designers, to ensure reasonable / safety / high efficiency mould design and ensure the fast mould delivery and rational mould structure, make the process more safer and the production efficiency more higher;

3. We using numerical control machine tool to manufacture the mould cavities, to ensure a even thickness ;

4. We using ZL104 Aluminium to casting the mould, to manufacture a high strength mould;

5. For the big mould, we using Ø22*1 copper tube as cooling pipe, with water spray system, to get a nice cooling effect;

6. We Have (TEF10N) coating on the mould surface, it can reduce the friction, anti water/static electricity/acid-base/high-temperature, with this we can ensure the pattern has smooth surface without distrotion, and easy to demould;

7. All the screws we using stainless steel screw, easy to disassemble during maintenance;

8. For the big mould chest, we using 18-20mm thick wrought aluminium plate, to offer high strenght cavity ;

9. For the complex mould which is difficult to demould, we can manufacture the automaitc mould with take out device ;

10. We produce the pattern sample to customer after finish the mould, when the pattern was qualified, then we do exceptance job for the mould ;

11. We have the Hexagon coordinate measuring instrument imported from the Switzerland to have a test make sure our mould qualified.

Company profile

Luoyang Liushi mould Co., Ltd was established on 2001, which is National Standard Setting Unit for Lost Foam Casting Mould. The company is located in the Millennium Emperor, peony flower city of Luoyang City. We have 9800 office building, and 22000 workshop, which is well equipped with research, development, design, foundry, machining, assembly, surface treatment and other equipment. It′s a Luoyang municipal R&D center and technology center.

Company technicians can provide on-site guide mould assembly, test production, free repair and complete technology for lost foam casting proecss according to customer demands. With the business philosophy of "careful design, lean manufacture, best service, perfect quality", we strive to provide satisfactory products and services for customers. After years of development, our company has become the preferred mould suppliers of many lost foam casting manufacturers and the exclusive supplier.